| BORODUR |

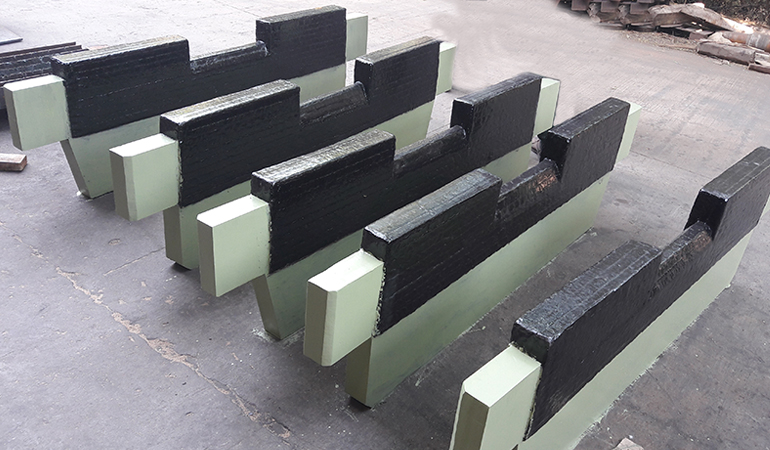

BORODUR wear plate gives, weld deposits of high C-Cr alloyed weld metal with excellent resistance to abrasion and mild impact. It can be used whenever high abrasion accompanied by corrosion is expected. Best results are achieved by two layers hardface wear plate. |

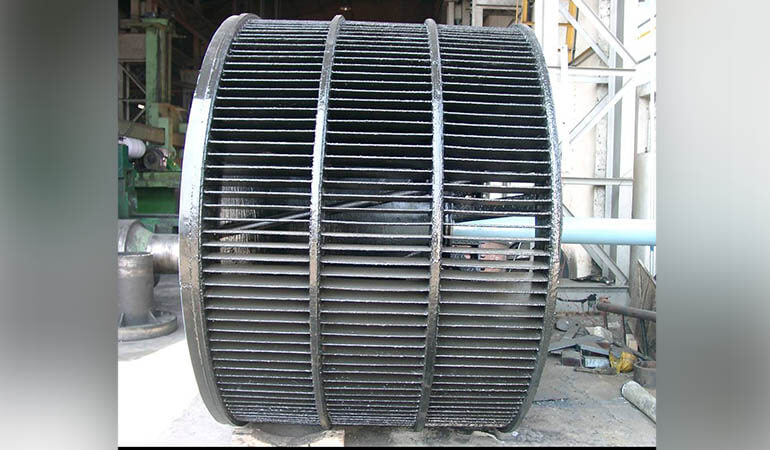

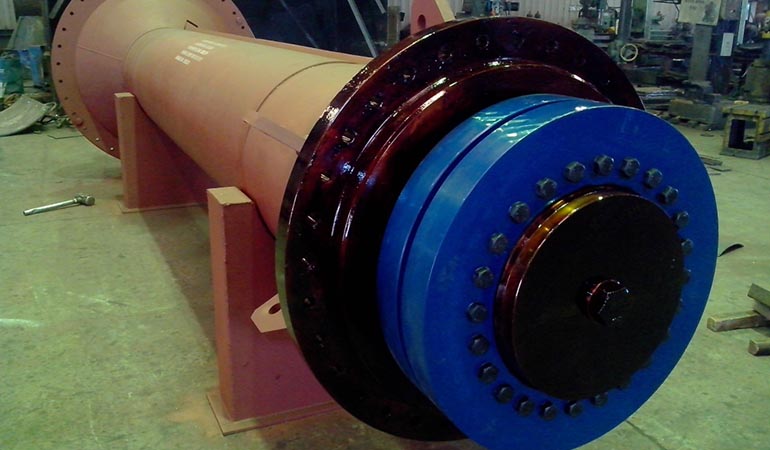

Pumps, mixer parts, tracks hoppers, Pipe, Impellers, Conveyer Screws, Coal and Cement Mill Tyres, Liner etc. |

56 – 59 HRC ( 4mm Weld Deposit)58 – 62 HRC ( 8mm Weld Deposit) |

C ,Si, Cr, B |

|

| CHROMADUR |

CHROMADUR is a wear plate, which contains a high C-Cr alloyed stainless weld metal with excellent resistance to abrasion. It can be used whenever high abrasion accompanied by corrosion is expected. Best results are achieved by double layer wear plate. |

Pumps, Impeller screws, Track hoppers, Bucket teeth. |

55 - 60 HRC ( On 4mm weld deposit) 58 – 64 HRC ( On 8mm weld deposit) |

C, Si, Cr |

|

| COLMODUR HT |

COLMODUR HT is highly alloyed C-Cr-Mo-Nb-W-V weld plate of extremely hard carbides. It is used for hardfacing and the weld metal has excellent abrasion resistance at high temperature. Weld deposit performs extremely well against strong mineral wear. The weld deposit retains its wear resistance up to 6500C.Best results are achieved by welding in two layers. |

Blast – furnace bells, fire grates, crusher, sinter wheel breakers, smelter loading chutes, etc. |

62 - 65 HRC ( On Three Layer) |

C, Cr, Mo, Nb, V, W |

|

| COLODUR |

COLODUR wear plate gives, weld deposits of high C-Cr-Nb alloyed weld metal with excellent resistance to extreme abrasion wear. COLODUR weld deposit consists of chrome and niobium carbides which offer an excellent resistance to abrasion. Best results are achieved by two layers hardface wear plate. |

Parts of coal mining equipment, steel industry, cement industry and mineral industries. |

58 – 61 HRC ( 4mm Weld Deposit)

59 – 62 HRC ( 8mm Weld Deposit) |

C, Si, Cr, Nb, Fe |

|

| ERODUR 801 |

ERODUR 801 is a specially developed wear plate, which gives highly alloyed deposit of Fe-C-Cr-Ni-B and other special alloyed elements. ERODUR 801 wear plate provides excellent resistance to severe erosion and moderate impact. The alloy primarily consists of carbides, borides and other complex carbides. It has excellent toughness for this high hardness range |

Hardfacing on parts of coal mining equipment, cement, steel and mineral industries subjected to fine particle erosion. |

60 - 67 HRC |

C, Cr, Ni, B |

|

| IMPACTODUR |

IMPACTODUR is a wear plate, which contains a high C-Si-Cr alloyed hardface weld deposit with moderate resistance to abrasion under high impact. Best results are achieved by double layer wear plate. |

Build up of crusher parts, bucket teeth and lips, trash crushing |

48 - 52 HRC ( On 4mm weld deposit)

51 – 55 HRC ( On 8mm weld deposit) |

C, Si, Cr |

|

| DIFFUSION CORDIFF TT 400 |

Cordiff TT 400 wear plate is specially deposited, with highly alloyed special metals for hardfacing of parts which are subjected to extreme wear and impact. The alloy primarily consists of primary Cr carbides and other complex carbides.

Wear plate has extremely wear resistant weld metal which standing intermediate strength of Impact. |

Used for hardfacing on parts subjected to extreme wear and impact. Screens, wear plates etc. |

48 - 55 HRC ( On 4mm weld deposit)

53 – 58 HRC ( On 8mm weld deposit) |

C, Si, Mn, Cr, Ni, B |

|